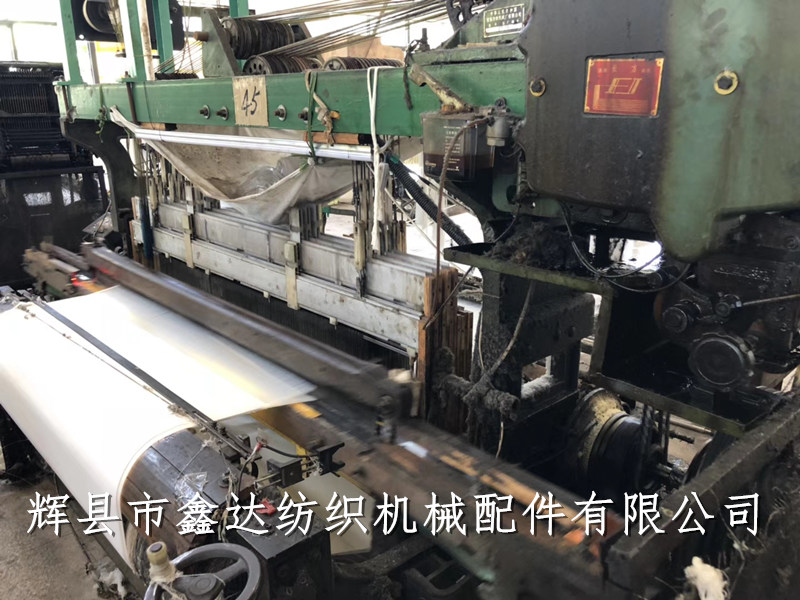

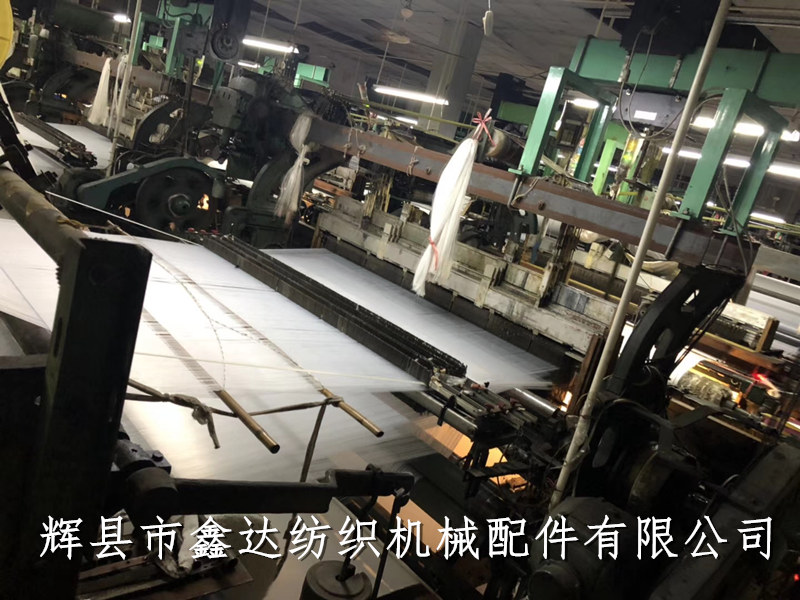

180 Hanrong loom is improved to shuttle loom on the basis of rapier loom. It can realize shuttle weaving of Hanrong fabric with door width of 180cm. The mechanical equipment is equipped with gt221 multi arm faucet. It uses multi piece heald frame to design the warp and weft structure. The equipment does not divide left and right hands, and increases electrical automation devices, greatly improving production efficiency. Hanrong, also known as worsted fabric, is a kind of clothing fabric woven from five satin fabrics. It has the characteristics of soft hand, wrinkle resistance and no pilling.

The frame of Hanrong loom borrows the rapier loom, the let off device is located at the back of the machine, and has one big and one small two warps, and the winding device is refitted to the back lower part of the weaving machine. Motor power 1.5kw, voltage: 380V

The machine adopts the weft insertion device and feeding part of shuttle machine, increases the function of weft breaking and self stopping, panel button operation, and selects the coreless shuttle of shuttle machine.

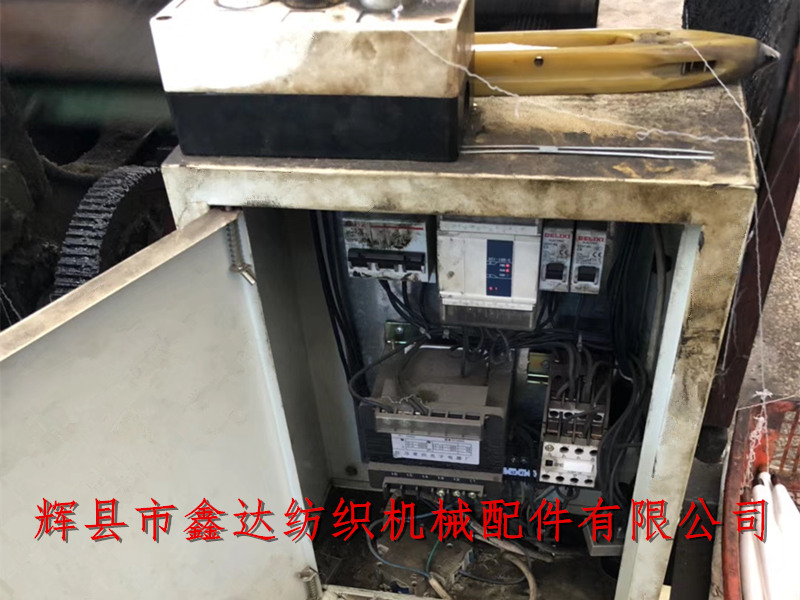

The stop device of Hanrong loom adopts local short circuit, and the control board controls the clutch to stop working. The structure principle is the same as that of rapier, and it has the characteristics of high sensitivity.

Interior drawing of control box of Hanrong loom. Hanrong loom, loom, loom refitting, domestic rapier refitting Hanrong loom.