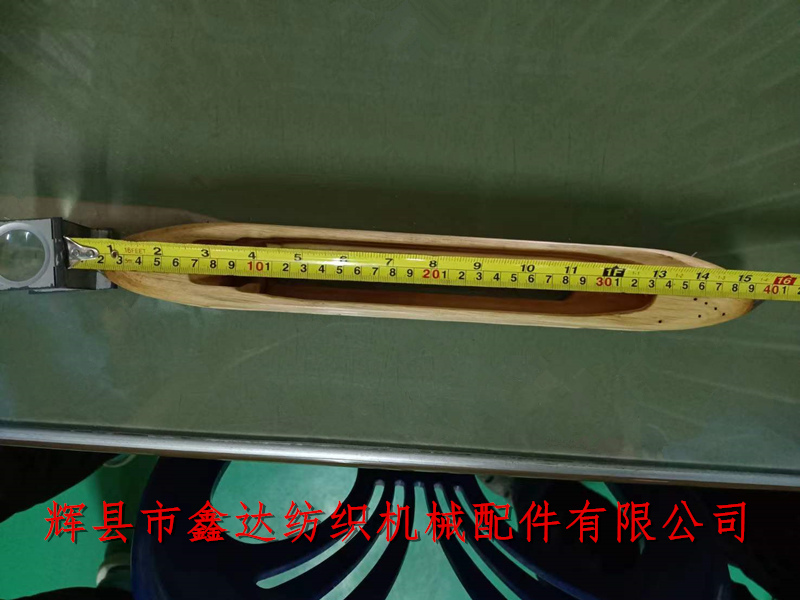

Our company provides customized Tsudakoma loom shuttles. Tsudakoma loom shuttles have a total length of 410mm, an external width of 46mm, an internal cavity width of 35mm, and a total height of 40mm. This shuttle is designed with a single spindle core. After the front is hollowed out, a glass fiber flexible (movable bell) is installed to improve the weft tension and reduce the weft shrinkage. Due to the difference between various nylon flexible sizes used in China and the original machine, the size of domestic accessories shall prevail in the production process, and the use effect of the finished Mata shuttle will not be affected.

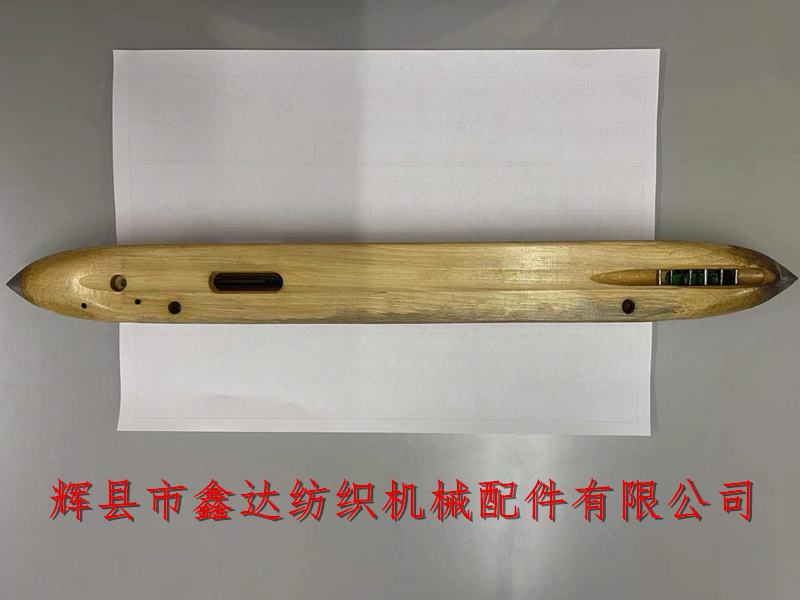

Two ends of Tsudakoma shuttle bottom are installed with a set of pin screws, mainly to prevent the wooden shuttle from expanding or deforming. The above figure shows the detailed picture of the shuttle on all sides. The shuttle is an effective carrier of weft for shuttle looms. There are strict requirements on the center of gravity of the shuttle body during flight. Tsuda Jumu shuttle can make appropriate parameter adjustment, but it is limited to the length, inner cavity design, weft angle, etc. (due to the size of the shuttle box, it is recommended that the width and height of the shuttle body should not be changed).

When producing Tsuda Jumu shuttles, the manufacturers of wooden shuttles select compressed wood materials that have been stored for many years, with a compression ratio of 1:1.15. The surface of the materials has fish scale patterns, which are characterized by high hardness, strong wear resistance, and weight of the shuttles. The rubber band or transparent rubber band is generally used to fix the flexible tail in China, and its effect is the same, both of which are to facilitate the flexible tail to be quickly reset after being pulled out by the weft yarn. The angle between the side of the shuttle (close to the back plate of the shuttle box) and the bottom of the shuttle is 86.5 degrees (the same as the angle of the shuttle of domestic looms).

The picture above shows a picture of the other side of the shuttle. The weft slot is located in the middle of the side of the shuttle body. On the right of the picture is a steel needle that is installed with flexible use. On the left, the round hole is used to install the shuttle post. The rectangle is a probe hole, which is used to detect whether the weft is used up when the shuttle stops moving.

The minimum order quantity of the textile Tsudakoma shuttle is 300 pieces. Normally, the delivery time is about 45-50 days. By default, full payment should be collected in advance. Packaging: carton+woven bag, 38 pieces per box. If you need to produce this Tsudakoma shuttle and Tsudakomu shuttle, please contact Mr. Yang of our company. We sincerely welcome your presence.