Xinda Textile Machinery Accessories Co., Ltd. provides textile equipment nylon heald (11 Inches steel wire heald eyelet). Nylon coated heald is a kind of weaving heald. It adds nylon coating process on the basis of 280 steel wire heald, mainly to improve the anti rust function of textile heald. Eyelet heald is required for dense fabric. Heald frames with the same length can arrange more steel wire healds, or reduce the friction and extrusion of adjacent healds. 280 steel wire heald refers to the hole (generally fisheye shaped) through which the middle lead of the small eye nylon heald refers to the yarn with an inner length of 280mm. The package of each package is 500 pieces.

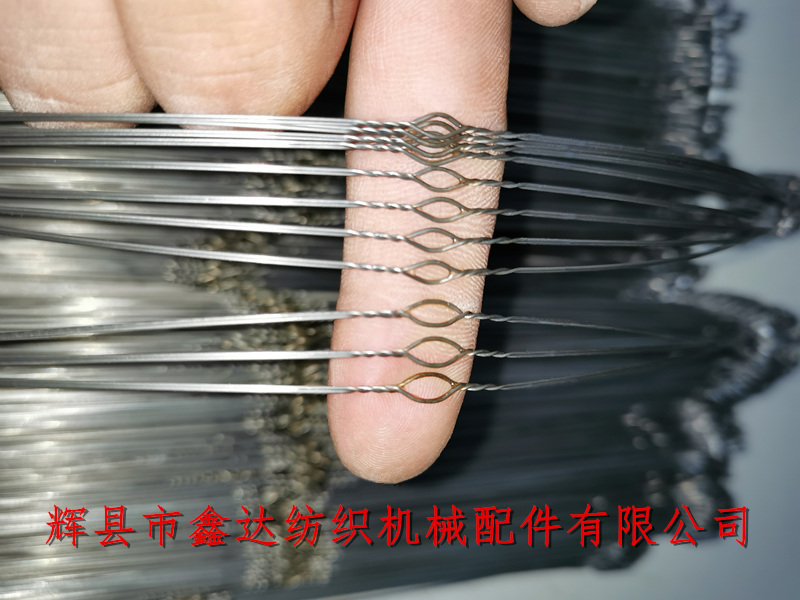

Eyelet wire heald (heald) is widely used in weaving machines. It is not only an important part of fabric warp movement, but also a necessary component for the formation of shed. Because it is used frequently in weaving machines, it consumes a lot of energy. The outer width of the middle hole of the small eye heald in the above figure is 3mm and the inner width is 1.7mm.

The above figure shows the comparison of A6 and A3 brown eyes (heald eyes). The big hole is A6 (below) and the small hole is A3 (above). The difference between the two inner lengths is 1.5mm and the difference between the inner widths is 0.3mm. The diameter of a single steel wire coated with nylon is 0.45mm, and the actual diameter of a single steel wire is 0.4mm.

The packaging of 280 * 0.45 * A3 special type steel wire heald products is 25000 pieces (50 packs) per box, the weight of each pack is about 0.37kg, the initial order quantity is 300000 pieces, and the delivery time is about 20 days. The inner length of the heald ears at both ends of the heald of textile equipment is 14mm and the inner width is 6.5mm. This heald can also be used on the automatic electric loom, and the use effect is obvious compared with the conventional one, which is mainly for the weaving of cotton fabrics.

Small eye heald is often used for hand weaving of ethnic minorities. This product can be used for brocade, scarf, silk scarf and other fabrics. Another important reason for choosing nylon coated heald is its low price. Considering the large friction resistance of nylon heald in the opening process, it is more laborious to step on the opening.