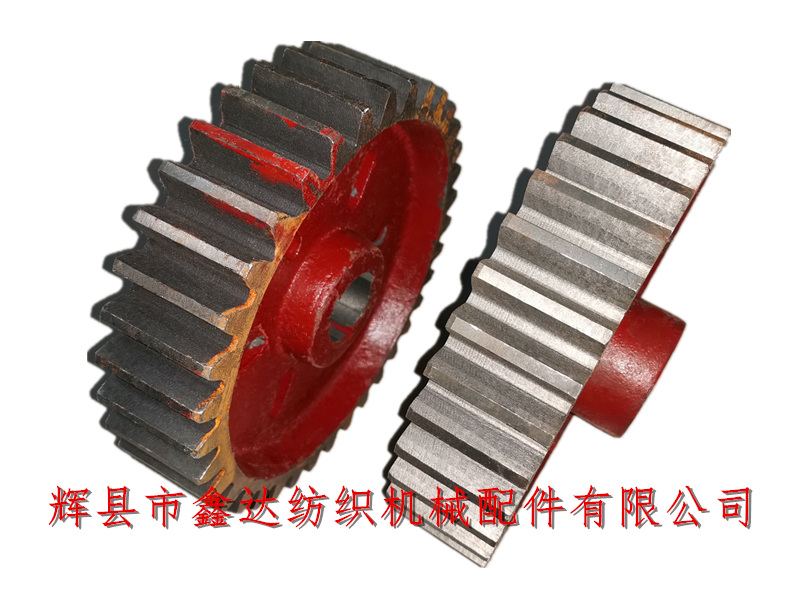

Xinda Textile Machinery Accessories Co., Ltd. provides 3210 loom gear ductile iron milling teeth [crank shaft gear] 1515. The parameters of the loom gear are: outer diameter 239mm, inner hole diameter 40mm, diameter pitch 4, modulus 6.35, gear height 7.8cm, tooth thickness 5.3cm, and the outer diameter of the middle round table is 67mm. The keyway of the milling gear has a width of 12mm and a depth of 2.5mm. It is suitable for 1515 looms with different door widths. It is matched with the bending shaft of the loom with a diameter of 40mm.

The material of 3210 crank shaft gear of textile machine is nodular iron (QT, which is a proportional mixture of gray iron and manganese steel). 36 teeth are processed by milling teeth, which improves the product accuracy. It is recommended to use milling nodular iron for its dual part E2.

The abrasion thickness of the shuttle action point of the tooth top of the loom gear 3210 is ≤ 1.6mm, the abrasion thickness of the tooth top of the non action point is not more than 1 / 2, and the wear of the keyway is not more than 0.3mm. It is not allowed to have gaps, missing teeth, broken journal and broken teeth. In such cases, please repair or replace them in time.

The 1515 loom gear (3210) is well meshed with the tread shaft gear (E2) (the end faces of the two gears should be flush and rotate flexibly), and is fixed on the loom crankshaft 3209. The weight of a single milling gear is about 5.8kg, which is slightly lighter than the ordinary tooth casting products of the same kind.

Textile gear, loom gear and shuttle loom transmission wheel play a key role in the whole transmission structure of 1515 loom. Their quality directly affects whether the machine can work normally and smoothly. 1515 gear, 56 inch crank shaft gear, 63 inch bending shaft gear and 75 inch crankshaft gear are vulnerable accessories. All textile enterprises should keep an appropriate amount of spare parts in stock.