Our company specializes in providing various black textile shuttle ts-9 carbon fiber injection molding products, shuttle length 390mm, shuttle bottom width 42mm, shuttle height 31.7mm, white nylon chuck fixed in the inner cavity of the textile shuttle, the effective length of the inner cavity 224mm, suitable for the use of the coreless tube with a length of 250mm, ts-9 nylon shuttle's yarn outlet is installed with stainless steel flexible, rubber band yarn blocking design.

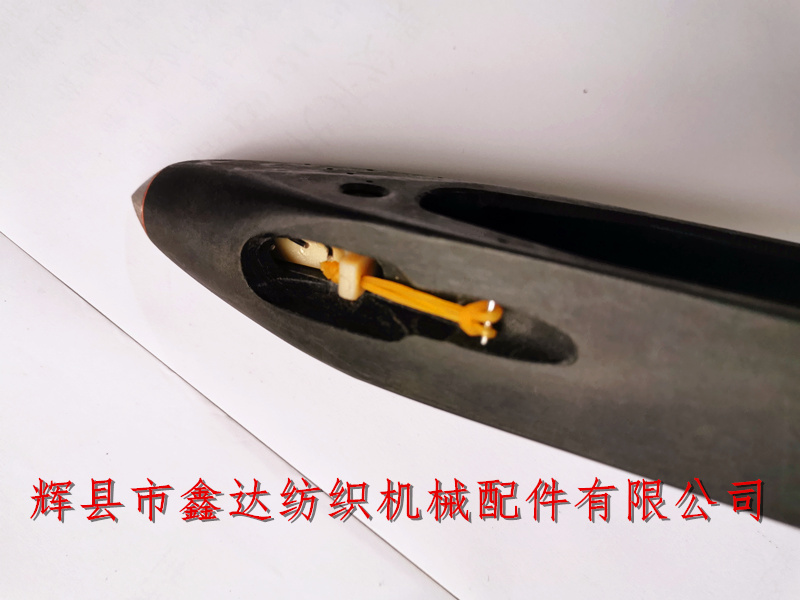

Ts-9 carbon fiber nylon shuttle is processed by a unique injection molding process. The inner cavity width of the upper opening is 30.4mm. The white porcelain eye is used to discharge the yarn. The direction of the weft and the tension are controlled by changing the direction of the flexible stainless steel wire, and the pin screw is used to fix the yarn flexibly. As shown below:

Textile nylon equipment, plastic injection shuttle processing, nylon flexible pin screw as the axis to swing left and right, yarn trough is located in the outer wall of ts-9 shuttle, weft detection slot at the bottom of shuttle, as shown in the following figure.

The processing material of textile nylon shuttle (export type ts-9) is carbon fiber, which is made by injection molding. It has high temperature resistance, smooth shape and is not easy to deform. Black powder will not fall during weaving.

The ts-9 nylon shuttle has seven steel needles, one fixed rubber band, four following the flexible clamping position, and the other two outside the shuttle help to control the weft direction.Ts-9,textile shuttle,injection shuttle,ts-9 shuttle,Black Textile Shuttle TS-9 Equipment.

Packing: Cartons, 50 per carton, 1000 per order, delivery time about 35 days. Xinda Textile machinery accessories is committed to the processing and customization of various abnormal and abnormal textile equipment accessories. We sincerely invite all textile enterprises and trading companies to cooperate.