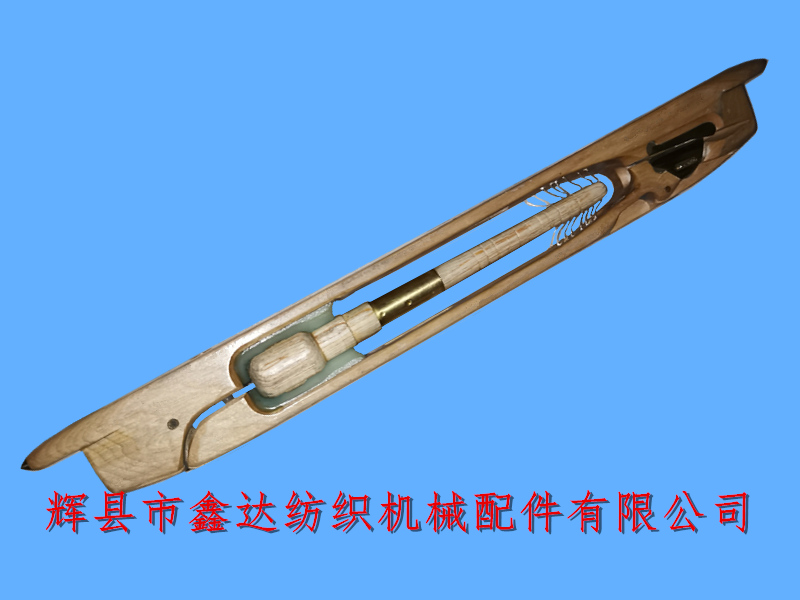

Huixian Xinda Textile Machinery Parts Co., Ltd. has long provided automatic replacement of skewed shuttles for small wooden shuttles. Eccentric Head Shuttle Customized By XinDa,Japanese loom spare part,Japan Shuttle,The distance between the two tips of this skewed shuttle is 466mm (the total length of the shuttle), the bottom outer width is 53mm, the upper outer width is 47mm, the inner cavity width of the lower part of the shuttle is 31mm, and the upper inner width is 32.5mm. The angle between the two side facades of the skewed shuttle and the bottom surface is different, and the outer side angle is relatively small, The total length of the inner cavity of the shuttle body is 234mm, and the length of the supporting tube is 220mm.

As shown in the above figure, each side of the shuttle is equipped with a nylon clamp on the inner side, and there is an expansion port at the rear. This expansion port is when the automatic thread changing action is executed. The downward movement of the weft tube (filament tube) will widen the inner cavity here, and the limit is controlled by the elastic force of the cow tendon below. The side photo is as follows:

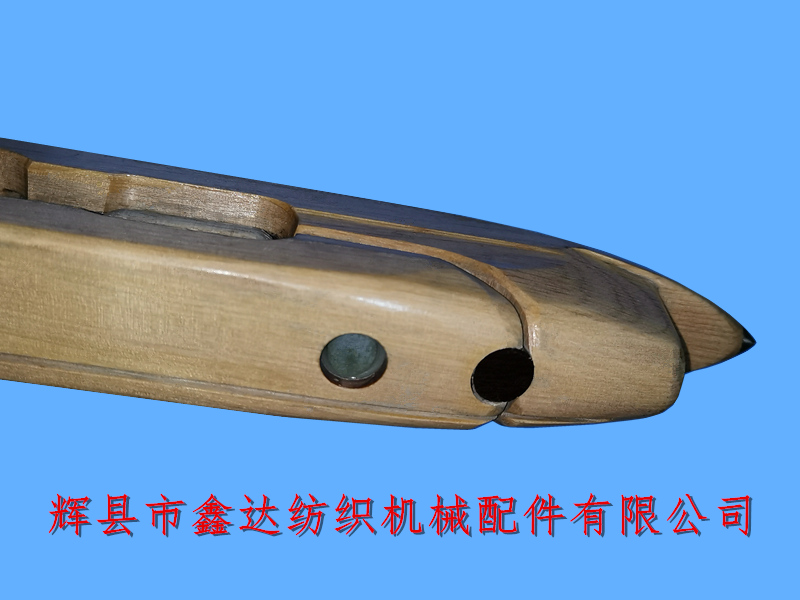

The left side of the above picture is a blue ox tendon, and the black cylindrical shape on the right side is used to assist in the expansion and reset of the weft insertion side expansion opening of the shuttle body. The diameter of the two circular holes is 12mm, and below them is a weft insertion groove with an internal width of 2mm. The tension type offset hook uses a smaller hook tip, but the mesh rod body at the tail of the hook tip is longer. This design is to increase the firmness of the hook tip and prevent it from falling off during use. The manufacturer of 430 offset shuttle, Toyota automatic replacement shuttle, and 466 small shuttle pointed wooden shuttle has more than 30 years of production experience and mature technology, committed to promoting the customized business of various models and specifications of wooden shuttles at home and abroad.

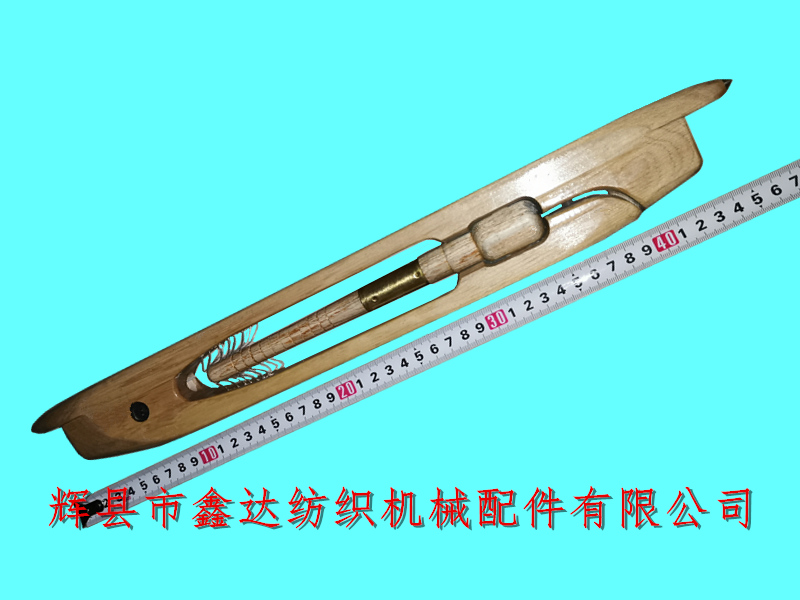

The above picture is a side view of the yarn feeder, with a length of 45mm and an inner width of 9.5mm for the side weft detection hole. Shuttle manufacturer's explanation: There are various specifications of the yarn passing device used for automatic shuttle changing, which are changed according to the design of the shuttle. The overall appearance design is relatively similar, and the efficiency of the offset shuttle is mainly reflected in the automatic replacement of the bobbin, which is different from the automatic shuttle changing in China.

The back of the 466mm * 53mm * 35.6mm offset shuttle is shown in the above figure. The minimum order quantity for the 466 offset shuttle is 300 pieces, with a delivery time of 60-70 days. This shuttle has high requirements for the material and processing accuracy of the shuttle body, and cannot be processed using spliced compressed materials or Aooka wood. Only the overall compressed wood material can be used for processing. If you need to order the offset shuttle, or find a wooden shuttle manufacturer, shuttle tip supplier, automatic replacement of weaving machine accessories, and special-shaped wooden shuttles, Please contact Manager Yang of our company for consultation!