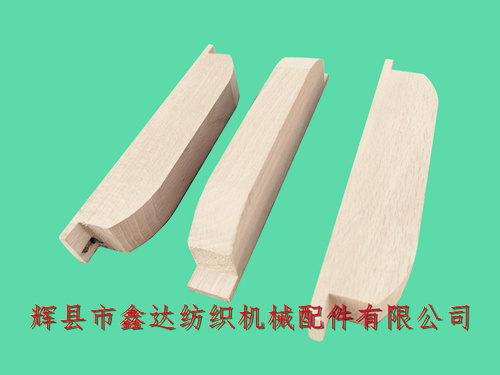

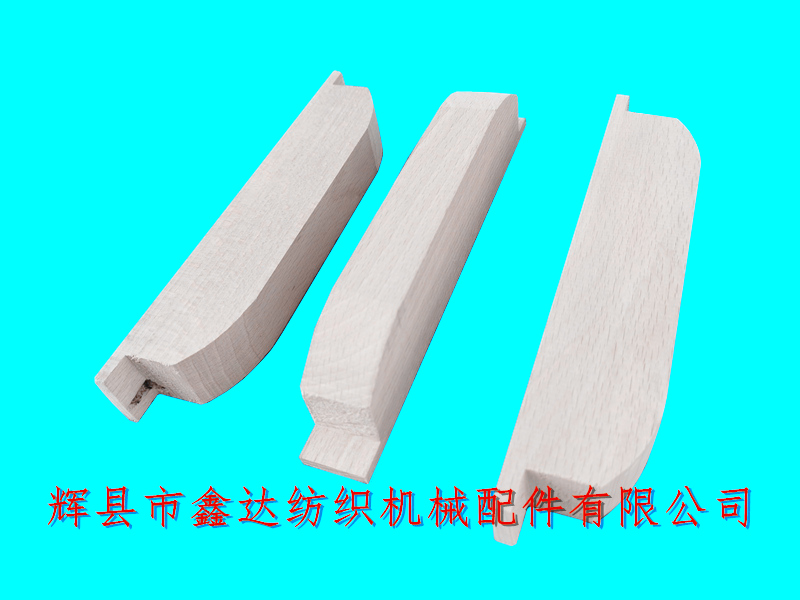

Huixian Xinda Textile Machinery Parts Co., Ltd. provides textile machinery and equipment all the year round, beech is used to process and Shuttles Brake Block 195*38*25mm,The Shuttles Brake Block is commonly used in the multi shuttle box of the multi shuttle loom. When the shuttle enters the multi shuttle box at a high speed, the protruding Shuttles Brake Block is used to reduce the speed of the shuttle and make it stop moving quickly, This type of shuttle wood is made of beech. The overall length is 195mm, the width is 38mm, the thickness is 25mm, and the length of the ears at both ends is 12.5mm, The width is 5mm.

In the traditional folk use of textile machine multi shuttle boxes, there are many modifications made based on the size of the shuttle and the characteristics of the fabric. They are generally used for weaving special material fabrics. The pressure spring on the back of the Shuttles Brake Block is used to prevent the shuttle from lifting up the Shuttles Brake Block, and the friction resistance between the Shuttles Brake Block itself and the side of the shuttle body changes in a curve shape according to the speed.

Shuttles Brake Block has the characteristics of moderate hardness, good wear resistance, smooth and delicate surface after wear, long service life, and good overall toughness. The minimum order quantity for Shuttles Brake Block products of the same specification is 200 pieces, with a delivery time of 20-25 days. The materials used for textile wood products are generally birch, beech, locust wood, green oak, elm, pine, etc.

Textile manufacturers, weaving mills and cotton mills all over the country can contact Mr. Yang of our company for consultation if they need to purchase or customize wooden products matching loom. We sincerely welcome you to call us for consultation! We have always adhered to the business philosophy of "honest management, pragmatic progress, mutual benefit" to solve the problem of accessory supply for various textile enterprises.