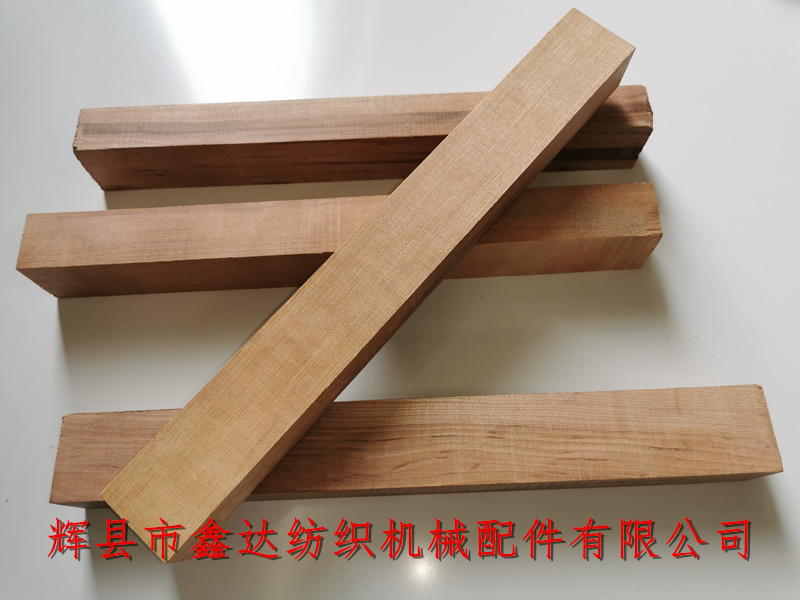

Huixian Xinda Textile Machinery Parts Co., Ltd. provides wooden shuttle blanks, birch compressed materials, and compressed wood for textile shuttles. This compressed wood material is initially screened and processed into wooden strips, which are then placed in compression molds to extract moisture and oil from the wood under high temperature and pressure. This treatment method can increase the fiber density of the wood and enhance its hardness. Generally, dozens of pieces can be pressed at a time, The compressed shuttle blank needs to be stored in a suitable environment for at least three years, which can completely deform the compressed material of the shuttle and to some extent ensure that the wooden shuttle is not easily deformed or cracked after processing.

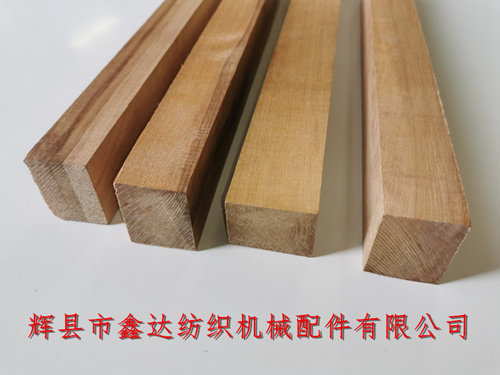

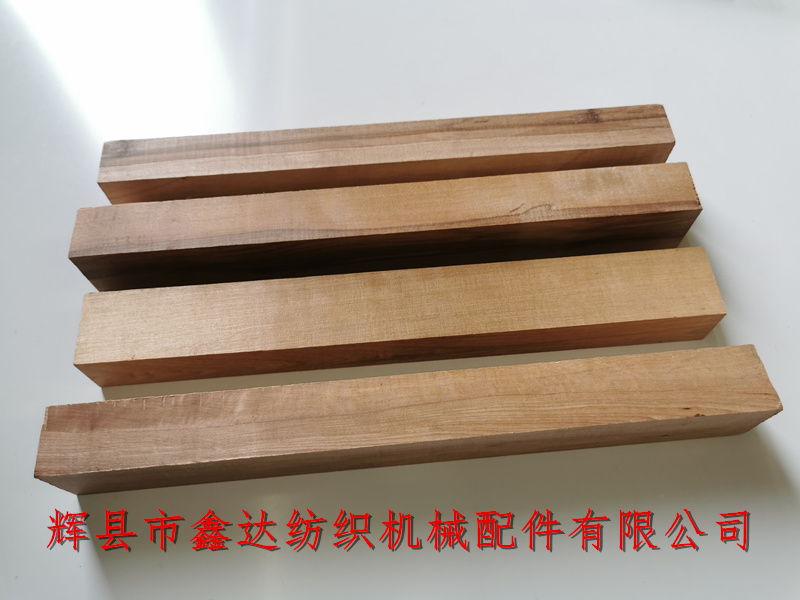

The above picture shows the wooden shuttle blanks and strips. Before being used to make wooden shuttles, the product needs to be processed into the shape shown in the picture to achieve a flat and smooth surface. Due to the different width and height of the shuttle (usually the width is greater than the height), the size of the processed blanks is slightly larger than that of the shuttle. Common materials include birch and elm, and some shuttles use green oak wood materials that do not require compression.

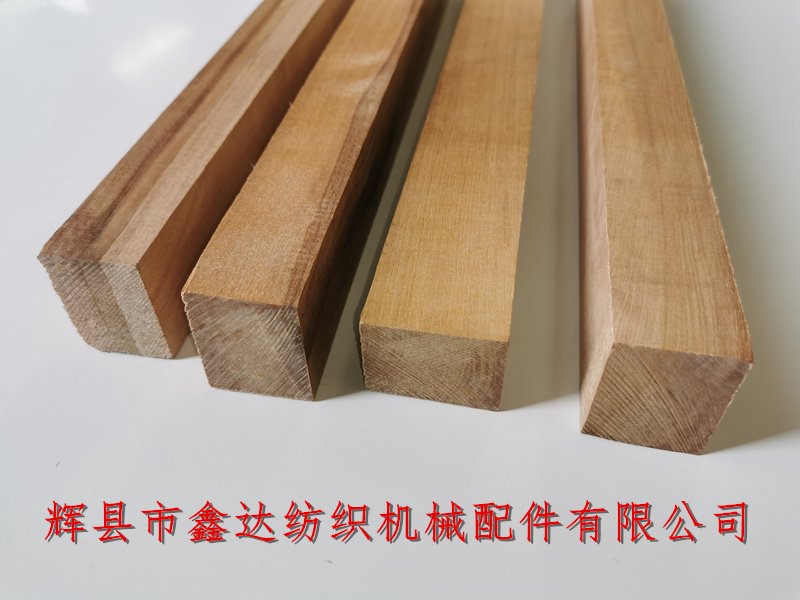

The shuttle blank (compressed wood) shown in the above picture differs in terms of the number of layers. On the left side, three wooden strips are compressed after being glued, and its cross-section has obvious layering lines. The common advantages of multiple layering are that using different woods for compression can reduce deformation.

The size of compressed wood is generally used with shuttles of lengths such as 34.3cm, 36.8cm, 38cm, 39cm, 40cm, 41cm, 42cm, 43cm, 55cm, etc. The individual length of the shuttle tips at both ends is about 1.5cm, that is, the length of the wooden strip+1.5 * 2=the total length of the shuttle, with a width of 50mm and a height of 40mm. Wooden shuttle blanks|Birch compressed materials|Compressed wood for textile shuttles can be used as a special raw material for various processing, and the surface of the finished product has a beautiful fish scale like texture, making it widely used. Due to the fact that the shuttle stock is compressed at high temperatures, it can be used to make other products with smaller sizes, such as bracelets, wooden jewelry, home furnishings, etc.