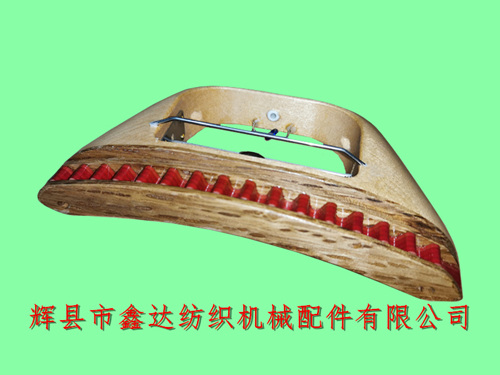

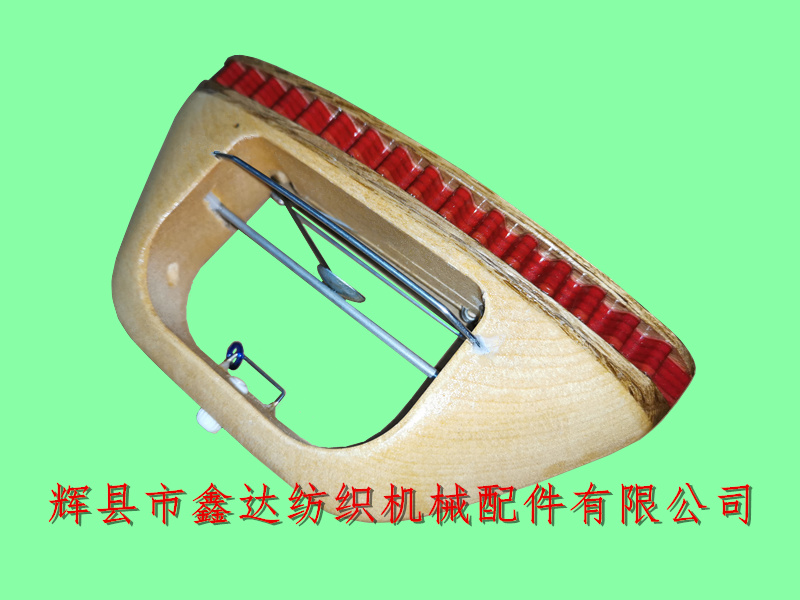

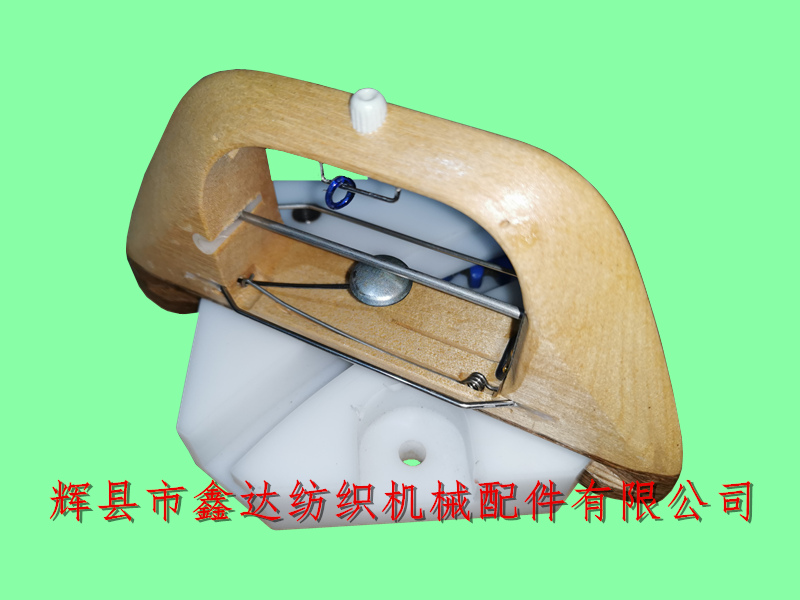

Huixian Xinda Textile Machinery Parts Co., Ltd. is engaged in the custom manufacturing of wood shuttles for ribbon looms. Shuttle manufacturers are engaged in the wholesale business of 160 curved horseshoe shuttles. Shuttle overall dimensions: total length 160mm, width 78mm (excluding ceramic eyes), internal length 76mm, internal width 49.5mm, and overall thickness (at the curved shuttle teeth) 29.7mm. In addition, textile shuttle manufacturers can also customize and process other kinds of wooden shuttles, including flat belt shuttles, cotton loom shuttles, glass fiber shuttles, Auto Change shuttle, fiberglass wooden shuttle, gunny bag shuttle, silk shuttle, etc.

The shape of the 160 arc-shaped shuttle is like a horseshoe. The red teeth in the picture are shuttle teeth, with a quantity of 16 teeth. The distance between adjacent teeth is 10mm. 10 Teeth\12 Teeth\13 Teeth\14 Teeth\16 Teeth Ribbon Loom Shuttle Factory,We provide customized processing services for the overall shuttle (except for the guide rod, glass ring, and tension spring).

The material of the main body of the loom shuttle is composed of Aooka wood and Yimu. The position of the shuttle teeth is Aooka wood (sturdy, wear-resistant, and highly stressed), and the front shuttle cavity is surrounded by Yimu wood (with moderate density and lightweight operation).

The quality of wooden shuttles for weaving machines with 160mm and other special specifications is stable, the production technology is mature, and the process is standard. The minimum order quantity for curved wooden shuttles is 100, and the delivery time is about 60 days. The specific judgment standard is whether the sample is complex.

Our company also provides multiple types of wooden shuttles, weaving machine shuttles, and horseshoe shuttles. Shuttle manufacturers need to receive full payment in advance before producing weaving machine wooden shuttles and customized shuttles. At the beginning of production, the cutting quantity will be appropriately increased, and the actual quantity will be settled separately after production is completed.