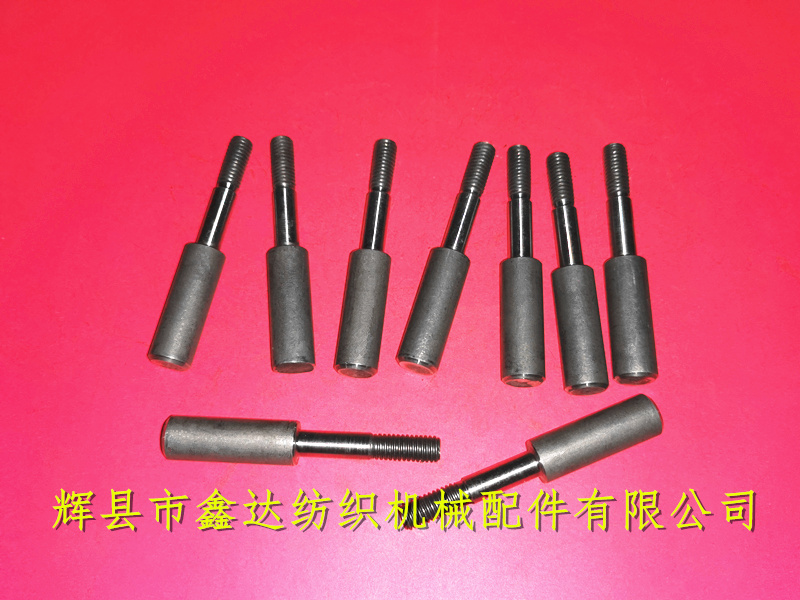

Huixian Xinda Textile Machinery Accessories Co., Ltd. provides the shuttle loom warp break part O104 fork angle pivot cap core, which is made of A3 (cold drawn). The total length of the O104 fork angle pivot cap screw core is 60.5mm, the outer diameter of the coarser part of the tail is 10mm, and the length is 29mm. Here, install the O9 fork angle pivot cap; The outer diameter of the front processing smooth surface is 5.8mm. Here is the O8 fork angle pivot. The front screw is M6, and the thread length is 14mm. Textile hardware accessories O104 fork angle pivot screw core belongs to the general accessories of looms, which is suitable for shuttle looms of model 1511/1515/GA615.

Textile hardware accessories -O104 screw core is used on each loom with a self sealing package of 50 pieces per bag and a minimum order of 10. Huixian Xinda Textile Machinery Accessories Co., Ltd. is a 1511 textile accessories manufacturer and 1515 textile equipment wholesale supplier, providing GA615 loom accessories, textile machinery accessories processing, and selling all kinds of shuttle textile accessories, dobby faucet accessories, multi shuttle loom parts, textile machinery equipment Textile hardware and tool equipment, textile porcelain parts, polymer accessories, shuttle special textile equipment, textile leather parts, 1515 wood equipment, plastic yarn tubes and other products.

The o104 fork angle pivot cap core, a broken warp stop accessory of shuttle loom, belongs to the processing parts of Yuan lathe. It is the spindle, bolt pin and small steel products of loom. Our company's main products: 44 inch, 56 inch and 75 inch nylon shuttle, steel wire heald, reed, leather knot, leather ring, shuttle rod and red steel paper and wood shuttle, and also deals with the adjustment of various textile machinery and equipment.

The function of warp stop device is to stop the loom immediately after the warp ends are broken, so as to reduce the weaving defects such as jumping, cobwebs and broken warp caused by warp breaks, and create favorable conditions for reducing the labor intensity of workers and improving the output and quality of fabrics. Regular maintenance shall be carried out during the operation of the warp break device, and comprehensive maintenance and correction must be carried out during the flat car.

If you need to purchase shuttle loom parts, fork pivot cap, warp break stop accessories, shuttle loom accessories, please contact Mr. Yang of our company for details. We sincerely welcome customers everywhere to negotiate and cooperate!