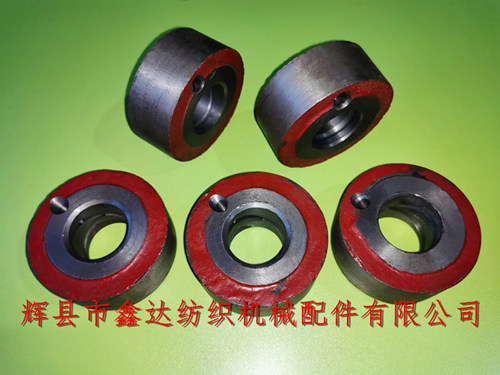

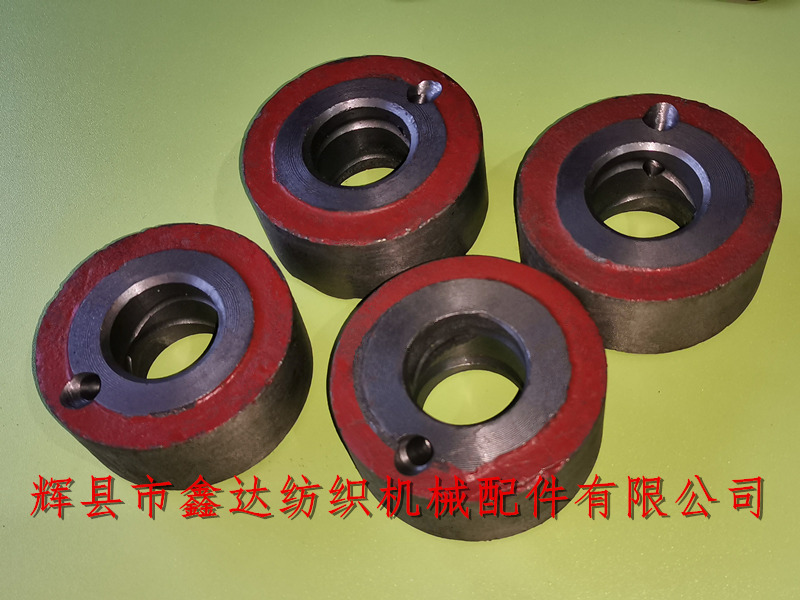

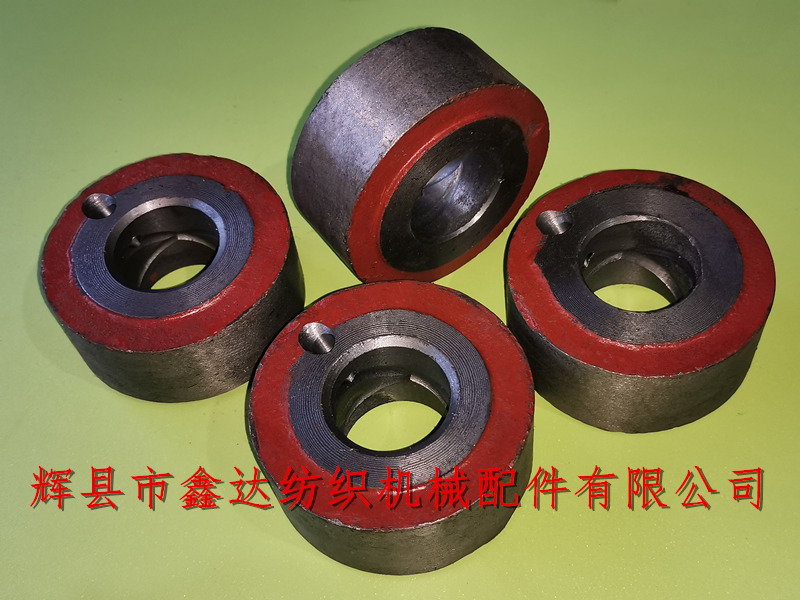

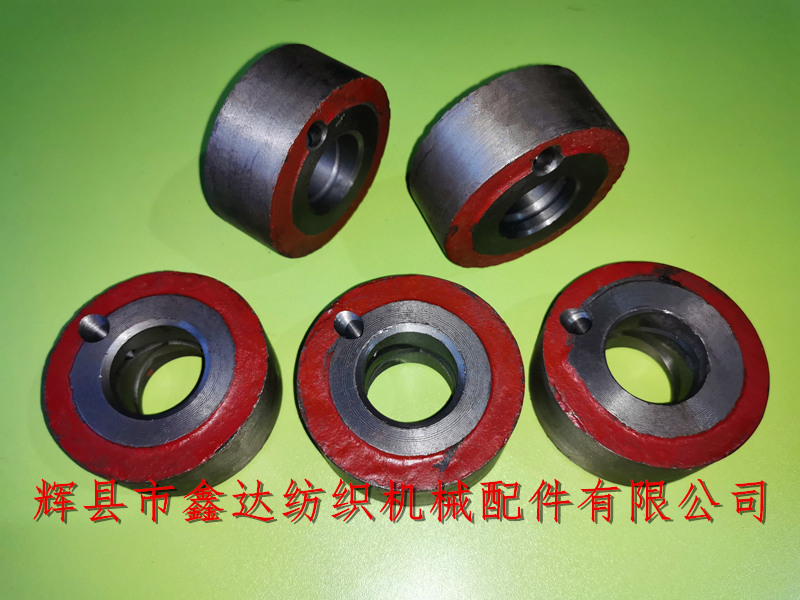

The ball iron shuttle rotor (picking bowl) of textile accessories F11 loom is respectively installed outside the wall panels on both sides of the loom. Each loom uses two.Shuttle Loom Spare Parts Picking Bowl F11, The mechanical shuttle device of the loom is mainly composed of the treading plate shaft and the shuttle plate, and the textile side plate applies force. The outer diameter of the shuttle rotor is 75.5mm, the inner hole has oil line, the diameter is 32mm, the thickness is 33.7mm, the single weight is about 0.8kg, and the color of the nodular iron rotor is red.

The diameter of the oil hole of the shuttle rotor of textile accessory F11 is 7.7mm, with an inclination of 45 °. The surface of the rotor is treated with cold hardening. The outer circle of the rotor can instantly realize the shuttle motion when the nose tip of the shuttle nose F4 is dropped down the slope of the shuttle nose.

Textile accessories F11 shuttle rotor can be used in 42 inch, 44 inch, 56 inch, 63 inch, 72 inch, 75 inch 1511 and 1515 looms. The rotor used in 1515k wide loom is different from this.

The shuttle parts of textile machine are the key parts of the operation of weaving machine, but also the vulnerable parts. The quality and production efficiency and production cost, reducing the number of maintenance, shortening the maintenance time and other details can effectively reduce the production and weaving cost.

We pay strict attention to the quality of products, optimize the proportion of textile accessories materials,Shuttle Loom Spare Parts Picking Bowl F11 and strive to provide satisfactory products and services for the textile factories. Welcome to contact our company for consultation and cooperation.