Weaving Spare Part O8 Conversion Rod Pivot for textile mills and weaving machine. The fork angle pivot of loom is made of pig iron and sand cast. Loom O8 (Conversion Rod Pivot) is a vulnerable accessory for loom warp break stop. The overall dimensions and Weaving Spare parameters of O8 used by Guangxi textile mill are: the width of two ears is 55mm, the width is 50mm and the height is 23mm; The inner hole is 7mm, and the O104 screw core is installed. The width of the clamping groove of the change rod O29 is 12mm and the depth is 3.5mm.

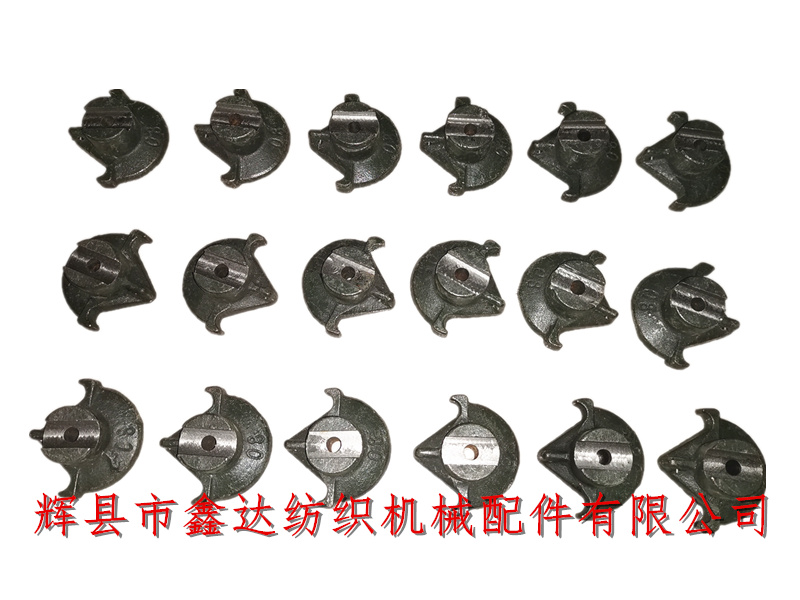

The inner hole at the nose of the front end of the fork angle pivot of the O8 loom used by textile mills and weaving mills is 3mm, which is used to fix the O42 combined rod spring (1.8 steel wire). The above picture is the front picture of the fork angle pivot O8 of the loom (regardless of left and right hands).GA615 Textile Accessories O8 Conversion Rod Pivot

Each loom in the textile factory uses one O8 (Conversion Rod Pivot) fixed on the outside of the O7 combined rod. This accessory is suitable for 1511, 1515 and GA615 shuttle looms of each door width.

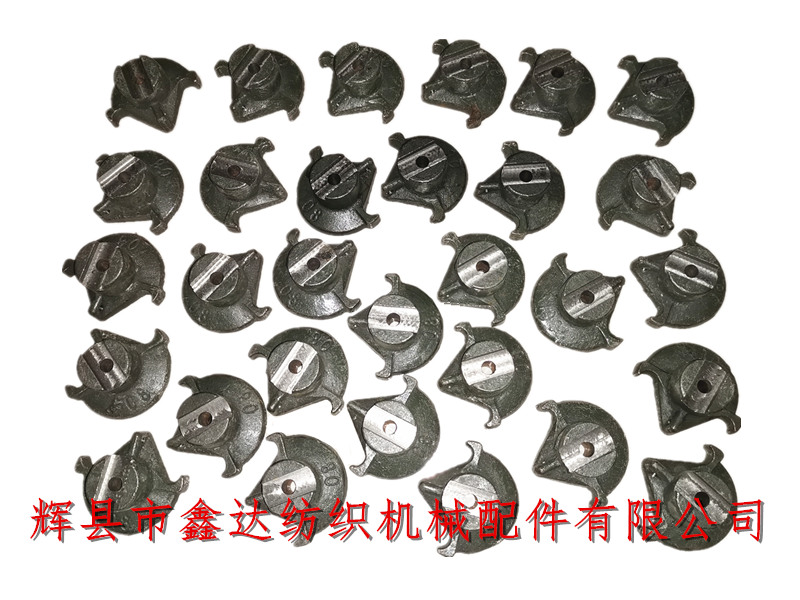

Package specification of textile accessories O8: 30 pieces in each string, and the weight of a single fork angle pivot is about 0.11kg. In the figure above, the back is processed into a plane by Yuan lathe, which is close to the smooth surface in the middle of the combined rod.

China textile factory parts, Nanning textile accessories and shuttle loom warp stop fork angle pivot are widely used. The fork angle pivot O8 is installed in the long waist hole of the combined rod. The upper and lower looseness is no more than 0.8mm, and the left and right lateral movement is no more than 0.8mm.

Check that the change-over rod O29 or 3614 is straight and installed in the groove of the fork angle pivot with a gap of no more than 0.4mm. Hang the spring O42, and the elastic force should not be too large. Pull the fork angle pivot by hand and return to its original position easily. The center of the change-over rod and the combined rod O7 shall be aligned exactly, and the high or low shall be corrected, which shall not exceed 1.6mm.