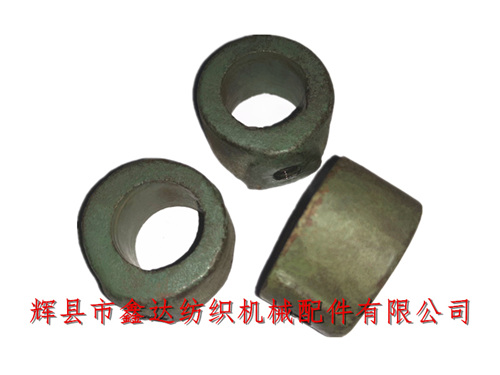

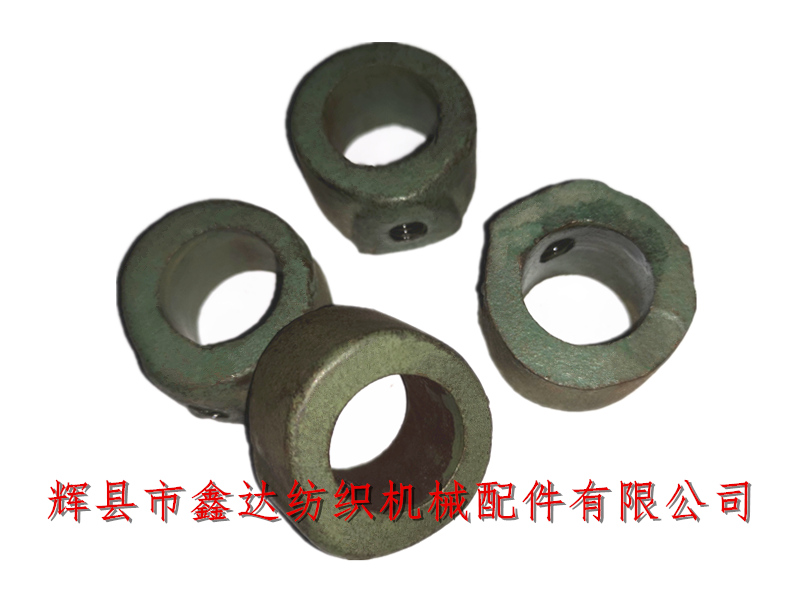

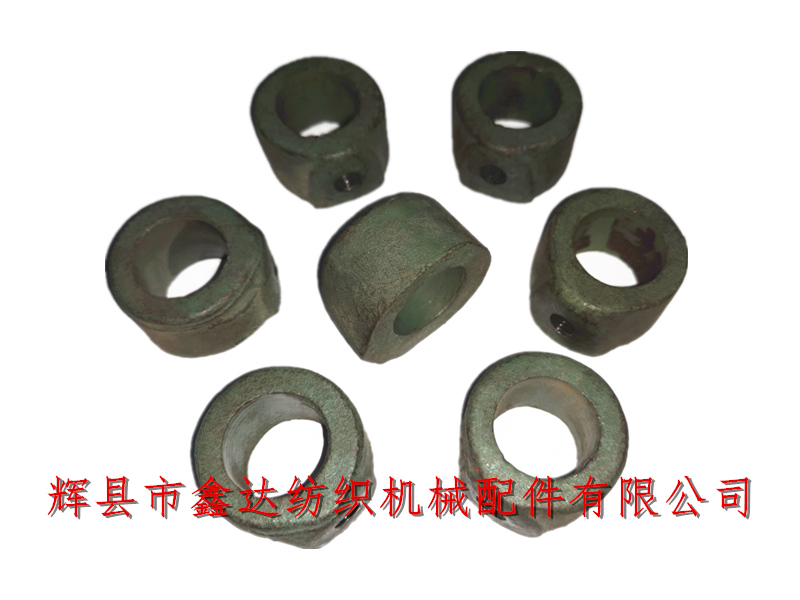

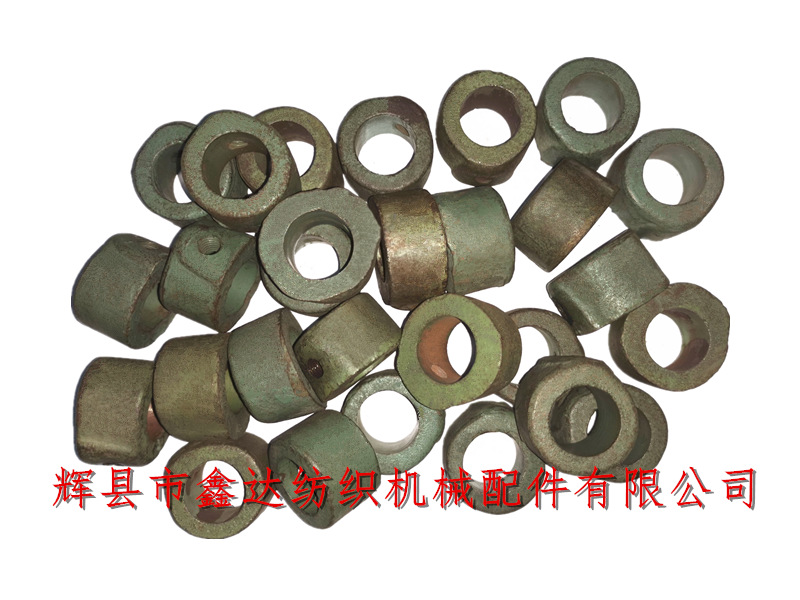

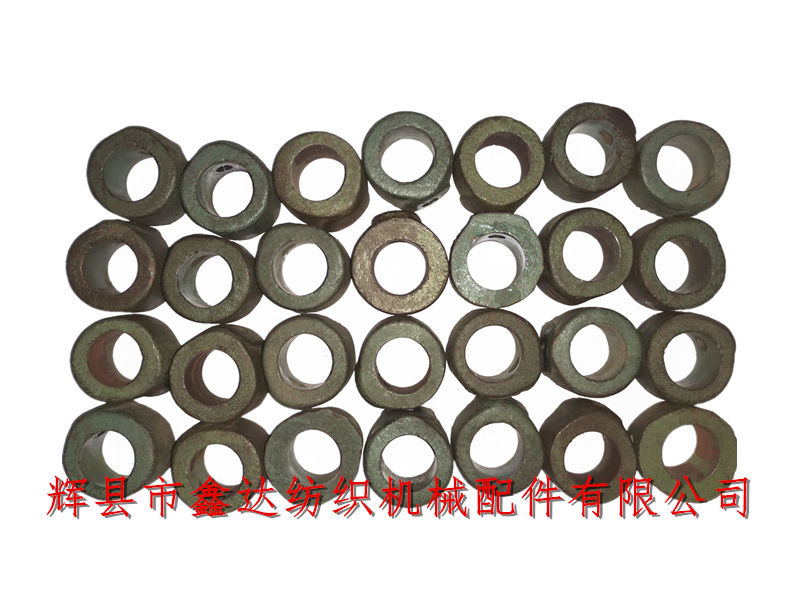

Our company provides all kinds of retaining rings and tight rings (neck rings) of the old shuttle loom. B42 Set Collar For Ratchet Wheel Shaft,The diameter of the inner hole of the B42 loom retaining ring saw gear neck ring (tight ring) is 22mm, the screw hole of the support head is M10, the tight ring, loom retaining ring, and the material of the loom neck ring is pig iron HT15-33. They are processed after sanding and casting and installed on the B12 sawtooth axle of the inner feeding loom. Each loom uses one, The weight of a single retaining ring is about 0.08 kg.

The cast iron sleeve of textile shuttle machine has a certain increase in price due to its low production capacity and reduced use year by year.Set Collar For Ratchet Wheel Shaft B42, The outer diameter of B42 saw gear tightening ring is 36mm (the shape is in slope shape, and this dimension is subject to the middle. The upper diameter is 35.5mm and the bottom diameter is 36.5mm). The outer diameter at the screw hole of the outer ring support head is 39.3mm and the height is 20.4mm.

Some old-fashioned 1515 looms also use the traditional inner let off device. The accessories used in the structure are roughly the same as those of 1511. Based on the change of adjusting rod and adjusting rod guide foot (G1515-4107), the shape is still the same.

B42 sawtooth wheel collar, Set Collar,Ratchet Wheel Shaft,an old loom accessory,Shuttle Loom Parts, can also be used as a retaining ring on other shafts with a diameter of 22mm. Its function is to fix the sawtooth shaft and prevent lateral movement during operation. The packing of tight ring, loom retaining ring and loom collar is 50 pieces / string, the color is generally green, and the thickness of one side wall of the retaining ring is 6.5mm.

The retaining ring of B42 loom belongs to the let off part. Its overall function is to control the conveying speed of warp yarn. Fabrics with different densities have different requirements for the let off speed. The general requirement of high output is that the let off speed is fast. Change the worm gear on the inner let off device The number of worm heads (the number of heads rotated from the tail, generally single head, double head, three head, four head and five head) or changing the tooth ratio of the let off bevel gear (the normal standard is 1:1, changed to 1.6:1 or 2:1) can realize rapid let off.