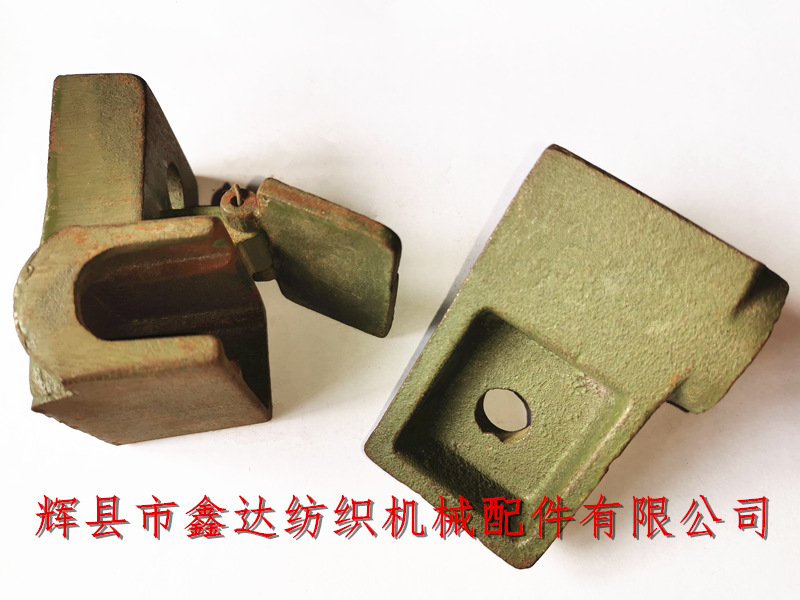

There is a shuttle loom accessories hanging heald base M5 and M3 hanging heald base cover (55mm long and 45mm wide). Their assembly is installed on the weaving machine crossbeam P6. Base M5 Of Lifting Heald Shaft For Shuttle Loom,The supporting feet M5 and M6 on the weaving machine hanging heald constitute the left hand and the right hand, which are respectively fixed on the M1 hanging heald base foot by one bolt. Each 1511 has one set of shuttle loom respectively. The weight of the lifting heald base is about 0.5kg. Material: gray iron 15-33 , color: green.

The diameter of the fixing hole in the above figure is 14mm. The overall dimension of the lifting harness shaft seat is 8.55cm long, 57mm wide, 48mm high in total, 2.9cm wide in the inner groove and 22mm thick in the base. The bolt shall be connected with wire less than 3mm to ensure that the cover can be lifted smoothly when replacing the cork bearing and refueling.

The groove in the figure above is used to install the q21 lifting heald wood bearing. The bases on both sides of the weaving machine beam P6 are installed face to face. The lifting heald shaft in the middle rotates back and forth. The two heald frames are pulled up and down by the lifting heald belt to realize the fabric opening in the weaving process of the 1511 single beam tatting machine, that is to say, the shed is continuously formed and opened and closed.

The figure above shows the back view of m5xm3 and the side view of m6xm3 of the lifting heald base. Various supporting feet of the upper crossbeam of the loom are used to ensure the smooth completion of lifting healds. More than 10 sets of loom lifting healds are available. Welcome to textile factories all over the world.