Massive Images Of Textile Equipment And Explanations Of Successful Cases

Textile equipment images include photos of weaving machines and spinning equipment. This article is about the massive collection of images of shuttle textile equipment in 2019, and combined with successful case studies, it enhances the understanding and cognition of our company's customized processing of textile equipment. The massive visual display of textile equipment images and detailed text introduction will give you a deep understanding.

Customized textile equipment according to customer requirements (343mm x 45mm x 35mm anti weft shrink shuttle). The wooden shuttle in the picture is designed with 3 porcelain eyes, with red steel paper on three sides, and a 180mm long weft tube is used.

According to the pictures of the textile equipment (small handmade wooden shuttle) produced by the customer, the length is 235mm, the external width is 34mm, and the height is 20mm. The weft yarn is led out from the side of the shuttle. The following picture is a comparison photo of the sample and the finished product:

The size of the handmade wooden shuttle processing is completely consistent with the sample, and the material is oil immersed compressed wood, forming fully.

According to the customer's requirements, the wooden shuttle was modified and the automatic shuttle was replaced with a manual shuttle. The textile equipment accessory - the yarn feeder was removed and replaced with a three ceramic eye design.

According to customer requirements, we provide automatic replacement wooden shuttle screws and standard parts processing to ensure product quality.

A 393mm long 3-ceramic eye wooden shuttle is shown in the above picture as a comparison between the sample shuttle and the finished shuttle. The finished product is made of three layers of red steel paper, with a shuttle height of 34.5mm and a width of 45mm

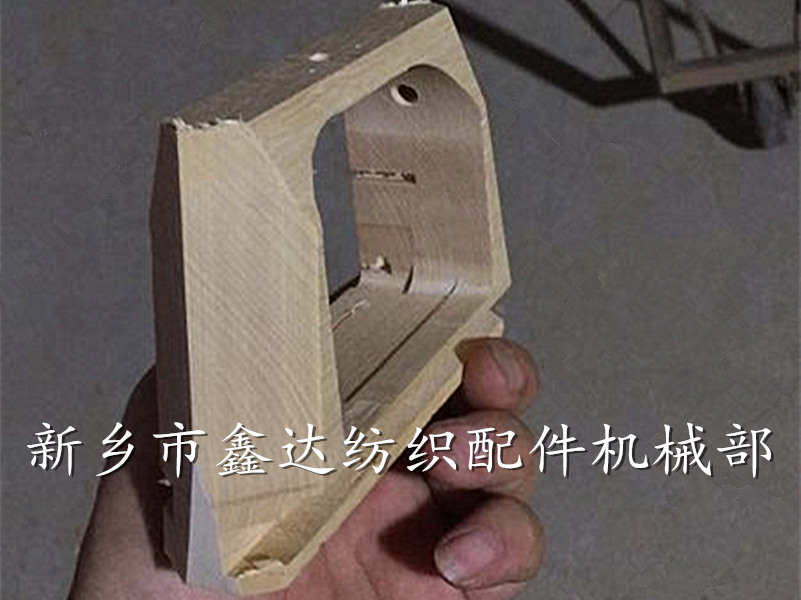

The semi-finished product of the flat shuttle of the weaving machine, as shown in the figure below, is a successful case of the finished product

The processing technology of this textile equipment is equivalent to that of imported parts, with a flat, smooth appearance, accurate angles, and a beautiful and elegant shuttle shape.

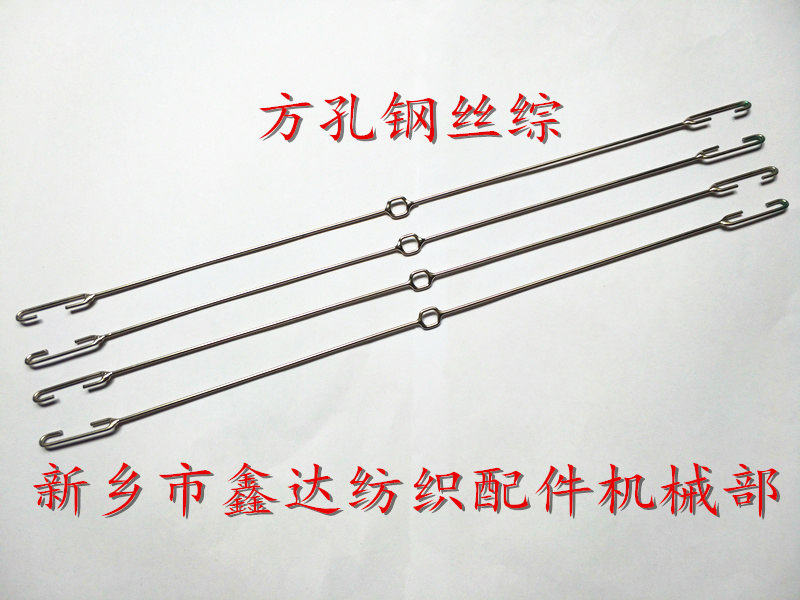

Picture of textile equipment (steel wire heald). The customer requested a square hole design because the warp shape of the fabric is flat. The finished product is as above, which is easy to install and has good passability.

The cumulative purchase quantity of two finished products, including steel sheet heald and small hole stainless steel heald wire, has reached over 200000 pieces.

The small handmade wooden shuttles and weft tubes (plastic 145mm) ordered by customers in Hainan are made of hardwood with good wear resistance and multiple ceramic eye designs. Suitable ceramic eye positions can be selected according to the weft tension requirements.

Photos of exported wooden shuttles and nylon textile equipment TS-7 shuttles. Shuttles account for a large proportion of textile equipment, with about 60 kinds of wooden shuttles. The applicable door widths of shuttle looms range from 0.5 meters to 16.5 meters. The application scope of nylon shuttles is generally limited to cotton looms and towel looms, with door widths ranging from 0.7 meters to 1.8 meters.

Wooden shuttles suitable for flat shuttle Ribbon Loom weaving machines

The multi arm brown frame pull hook ordered by a Myanmar customer, abbreviated as "free hook", is suitable for multi arm looms with multiple door widths.

Various types of fiberglass shuttles with flexible and fixed screws, nylon flexible and red steel paper flexible, with different lengths, including three ceramic rings, two ceramic rings, and one ceramic ring. There are three types of pin screw diameters, which are selected according to the size of the flexible and the material of the shuttle.

The shuttle seat used in the arc weaving machine has a double gear version, and the shuttle seat requires strict processing technology, with errors strictly locked within the range to ensure smooth operation of the shuttle.

The shuttle seat used for ordinary 10 tooth curved webbing wooden shuttles is pressed with red steel paper for transmission gears. The curved shuttle swings left and right on the adjacent two shuttle seats to complete the weft insertion action.

Three customized cowhide shuttle knots (leather knots) are available in three sizes: large, small, and medium. The leather tongue (referred to as leather tongue) of the medium and small sizes is made of rubber material.

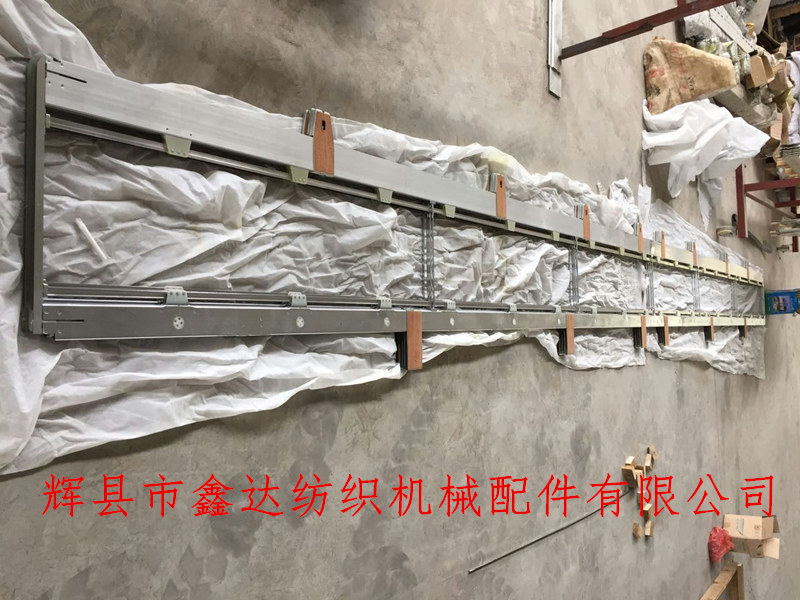

Two customized Sulzer TW-130 inch gripper looms were retrofitted with one 260 inch brown frame, which belongs to the hardware textile equipment category. The length of the gripper brown frame reaches 7.3 meters, and reinforcement ribs are added to ensure the stability of the gripper heald frame.

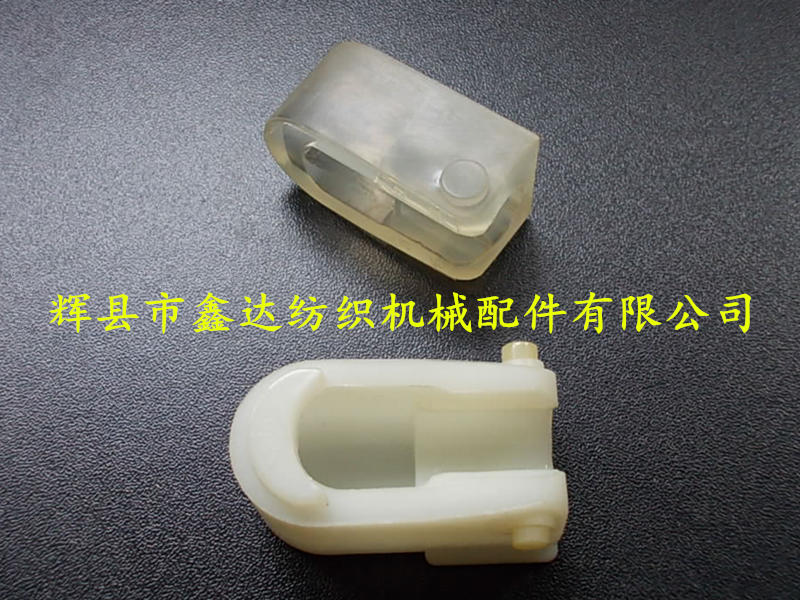

Comparison of PU chucks, nylon materials, and plastic materials used for coreless and silk weaving shuttles.

Photos of textile equipment (180 weft tube) processing, physical photos taken, with no fixed slot at the bottom of the tube. The stunning product color and stable product performance indicators satisfy customers.

Customized arc-shaped ribbon weaving machine rack is used to drive the shuttle seat gear to rotate, achieving left and right swing of the ribbon arc-shaped shuttle with a tooth pitch of 11mm.

The middle is a sample shuttle, and the two sides are finished shuttles. There are many types of customized wooden shuttles in textile equipment, so not all of them will be uploaded here.

With the above simple successful cases (comparison between samples and finished products), it can be intuitively understood through pictures of textile equipment.