Shedding Cam, Multi Arm, And Jacquard Opening Mechanism Of Broad Loom

The tread plate, multi arm, and jacquard opening mechanism of a wide width loom require the warp and weft yarns to be interwoven into a fabric by first dividing them into upper and lower pieces to form a shuttle opening. The process of separating the warp yarn up and down is called opening, which is completed by an opening mechanism. The opening mechanism not only needs to separate the upper and lower warp yarns to form a shuttle opening, but also needs to control the lifting sequence of the warp and weft frames according to the process design requirements, so that the fabric can obtain the required warp and weft structure.

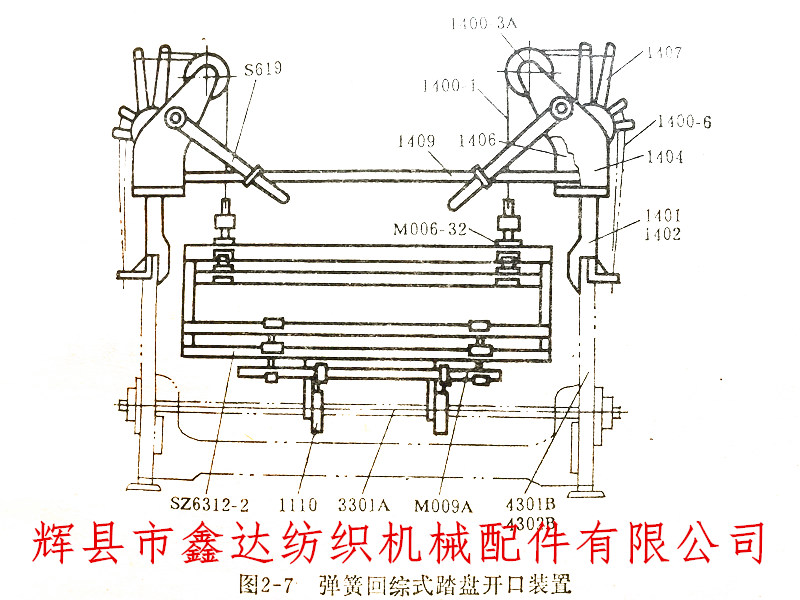

For this purpose, when weaving different types of fabrics, corresponding opening mechanisms need to be configured. Usually, simple plain weave, twill weave, and satin weave fabrics are woven and managed by the same device for the lifting and sequence of the frame. The inner passive tread opening mechanism is of this form, also known as the cam opening mechanism.

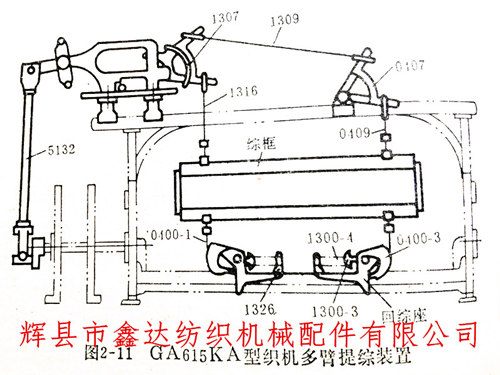

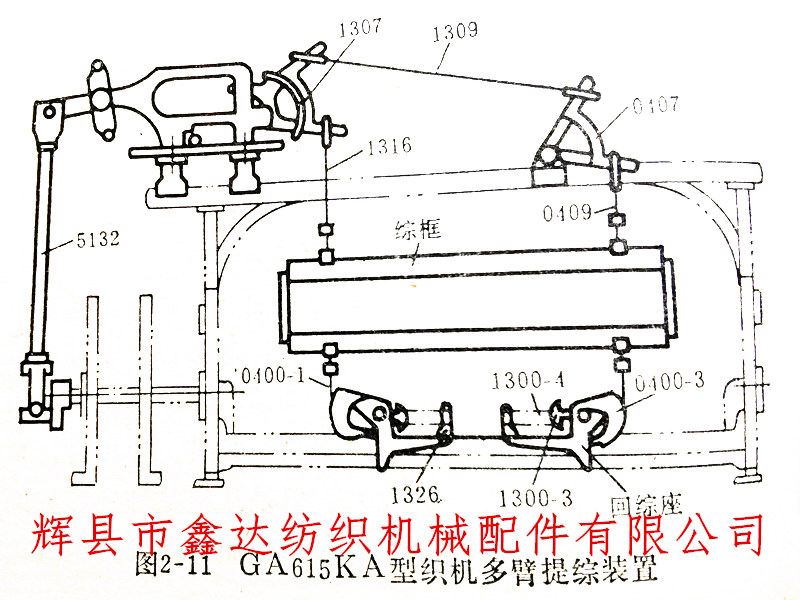

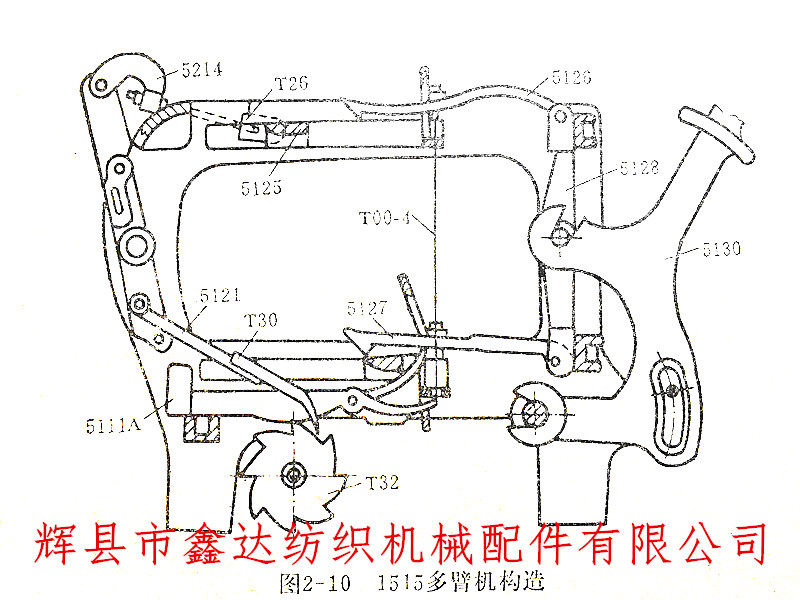

When complex fabrics need to be woven, a multi arm opening mechanism is used. Its frame lifting and lifting sequence are respectively achieved by the lifting device and the pattern plate conversion device on the multi arm machine, which can weave small patterned fabrics within 16 pages of the frame. When weaving complex jacquard fabrics with large patterns, one mechanism manages the warp yarn lifting, while another mechanism manages the formation of patterns. This is the combined jacquard towel opening mechanism composed of a tread plate fuzzing device and a jacquard faucet.

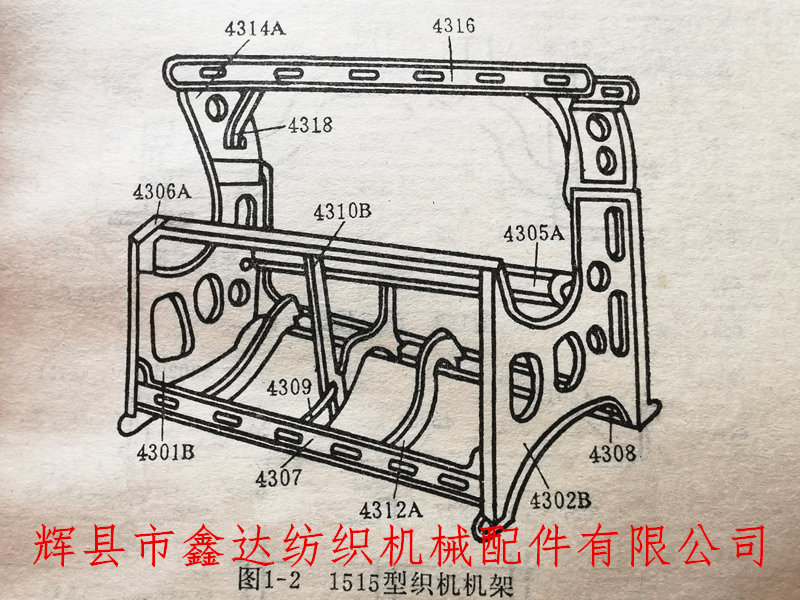

The opening forms used by GA615 and 1515 wide width series looms mostly belong to two types: the inner passive tread opening mechanism and the single drum reciprocating multi arm opening mechanism. Towel and single sheet looms also need to be equipped with TK212 jacquard devices (or jacquard faucets).

Jacquard mechanism, multi arm mechanism, tread mechanism, wide width weaving machine.