Correction Method For Opening Time Of Twill Loom

Through observation and analysis of the twill loom, it is not difficult to see that according to the usual weaving method, the opening time of the calibration loom needs to be changed in order to interweave the edge yarn and weft yarn. If the shuttle is in the right shuttle box, the edge yarn on both sides cannot be interwoven with the weft yarn to form a fabric. This article provides a simple method for calibrating the opening time of the twill loom (taking the 1511 model as an example). The opening time of the twill loom is the key to fabric forming and requires skilled maintenance personnel to master it.

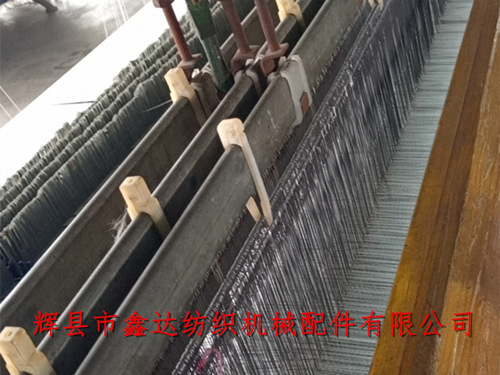

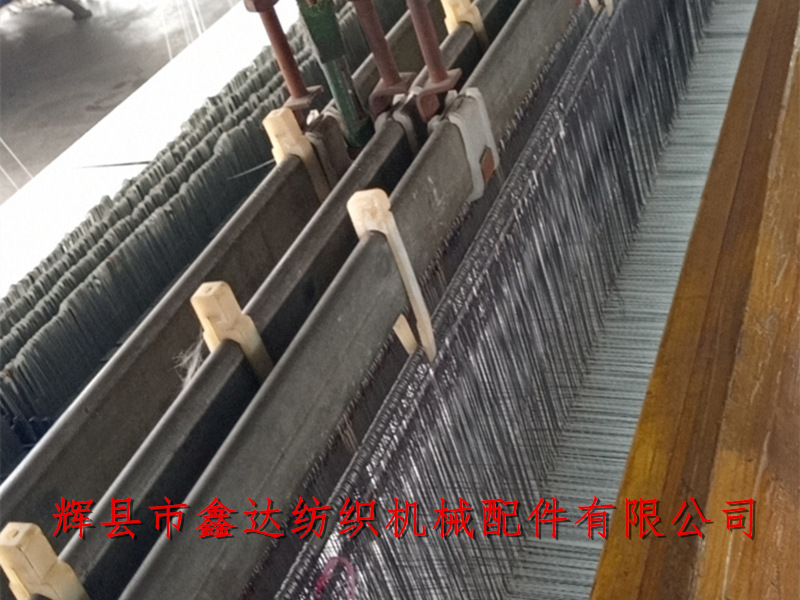

Regardless of the diagonal weaving machine with left or right hands, when the shuttle is in the left shuttle box, the bending axis is in front of the center of gravity, and the distance between the steel reed and the chest beam is 203.2mm (8 inches), adjust the 1 and 3 tread rods of the weaving machine to be level. 1 is the long tread rod, and at this time, the fourth page of the weaving frame is on the top and the second page of the weaving frame is on the bottom. Move the crack gear to mesh with the bridge gear, and tighten the screw when it is tightened upwards. Move the plain weave tread closer to the weft cam and fix it on the tread shaft of the twill loom.

When calibrating the opening time of diagonal weaving devices, not only should the flight conditions of the shuttle be considered, but also the correct alignment between the position of the frame and the direction of the shuttle should be taken into account; The diagonal device is divided into two upper and two lower (2/2), 1/2, three upper and one lower (3/1), and four upper and one lower (4/1), and their calibration methods and principles are the same.

Install gear cover S34 so that it does not collide with the gear, then install pedal cover S37, lower the height of the rear pole bracket, remove the stable motion rod (or place it upside down on the support foot of the stop frame), so that the rear beam does not swing.