Instructions Of Loom Manufacturers On Various Weaving Machines

The Loom manufacturer is a general and vague statement, which generally represents the manufacturer of all kinds of weaving machinery and equipment. According to the different weaving processes and weaving links, it can be divided into a variety of machinery and equipment, such as warping machine, rapier machine, circular loom, shuttle loom, glass fiber machine, embroidery machine, warp knitting machine, cross knitting machine, etc. We simply provide some pictures of such equipment for explanation, Easy for entry-level textile peers to understand and learn.

Multi head embroidery machine equipment is generally used for embroidery after weaving, also known as embroidery machine, which can draw and weave patterns of different shapes with high efficiency. High speed flat embroidery machines are commonly controlled by computer programs and use servo motor single head control, which has a good energy-saving effect. The machine speed is 300-1200rpm, and can generally be used for towel embroidery, coil embroidery, and bead embroidery.

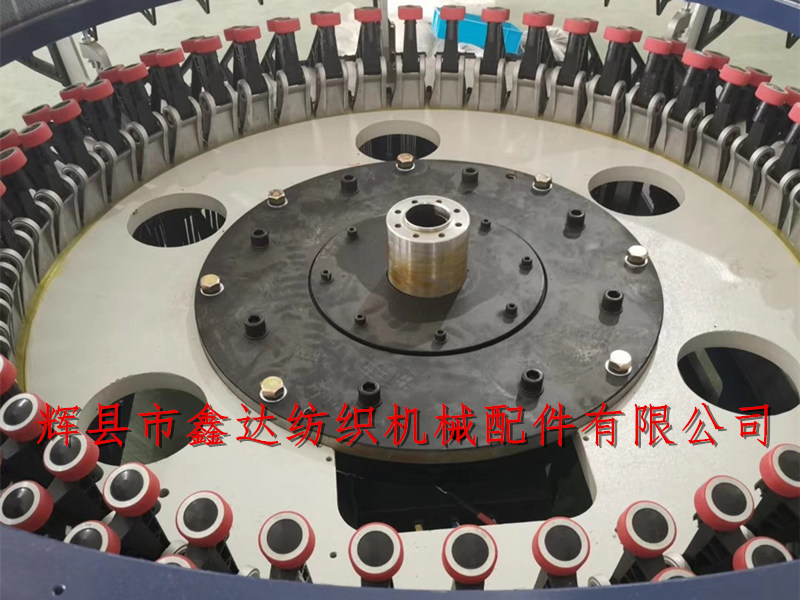

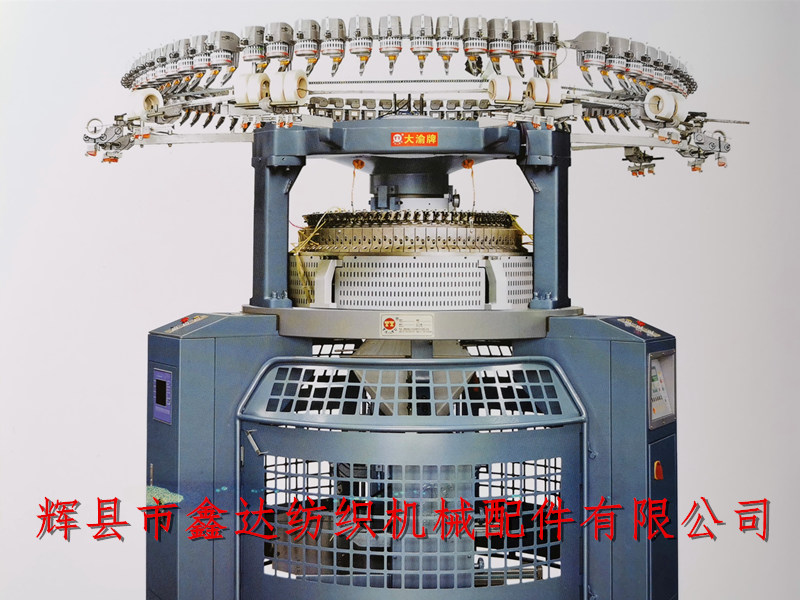

The installation diagram of the circular loom track is generally used for producing cylindrical products, belonging to the knitting machinery. The large jacquard machine can weave twill, air layer, interlayer and cushion foam, stair cloth, double-sided bead ground, silk cover cotton, rib, elastic double-sided cloth, etc. The pattern design is edited using universal drawing software, making it easy to change the pattern and efficient.

The high-speed single sided knitting machine can weave floating pattern fabric, fish scale fabric, small jacquard, industrial fabric, colored polyester fabric, etc. The addition of double yarn equipment can weave elastic fabric.

The weft tube of the disc Loom is fixed on the disc device, which is convenient for automatically changing the weft tube clockwise after the weft is used up, simple and efficient.

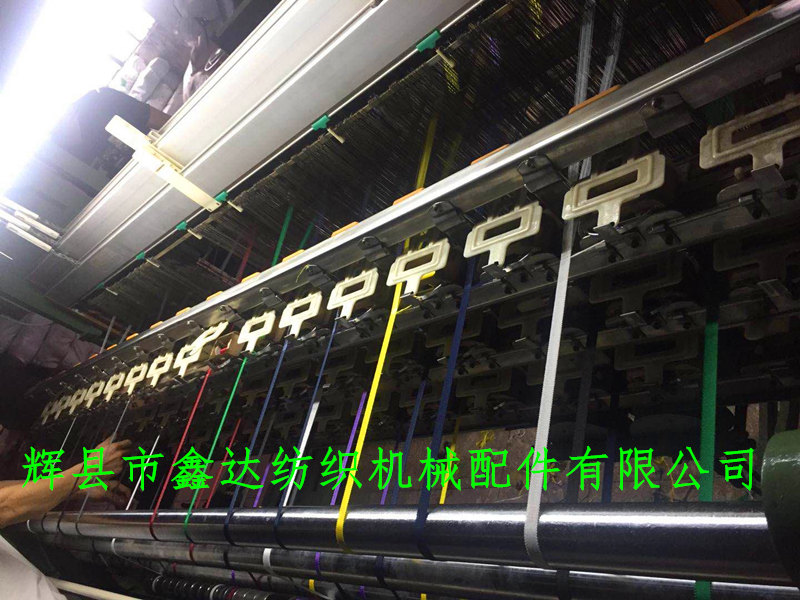

K611 silk loom equipment with multi arm device. The use of specialized brackets to fix the warp axis is to increase the length of the horizontal warp yarn, reduce the angle of the warp yarn direction, and reduce warp breakage faults. Each type of textile equipment has corresponding manufacturers, Loom manufacturers are distributed all over the country, and the textile industry Ghetto generally produces the same kind of textiles.

A simple 40 spindle weft winding machine equipment, with an elongated triangular drive that drives 40 supporting rollers to operate. The weft tube fixed on the spindle is squeezed and wrapped around the weft yarn by two adjacent supporting rollers.

The functions of the multi-layer shuttle box ribbon loom, the three-layer flat shuttle ribbon loom, the ribbon loom, hat belt loom, collar label machine, embroidery machine and other textile machinery and equipment are widely used. Before purchasing a Loom, you need to know more about its supporting equipment (warping machine, weft winding machine, cloth coding machine, packing machine, sizing machine, sewing machine, wire drawing machine, doubling machine, etc.).